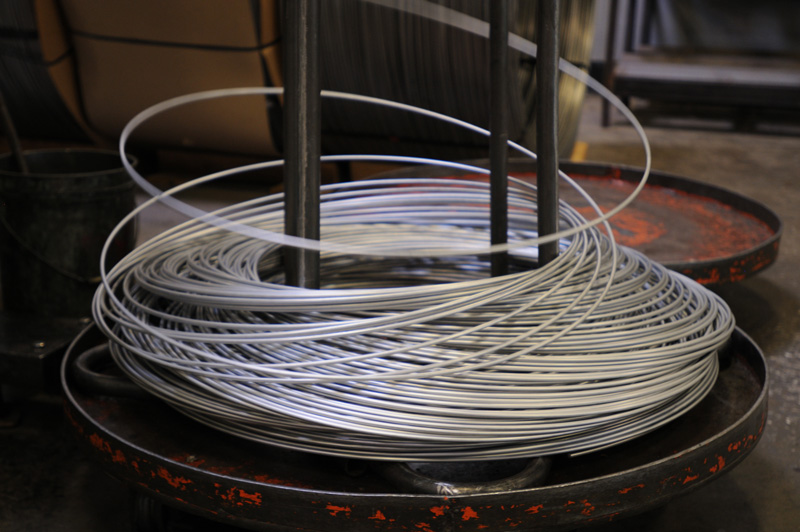

Producing high quality aluminum wire takes more than highly trained staff. It requires a facility with all the necessary resources to make the commitment to quality and service a reality…

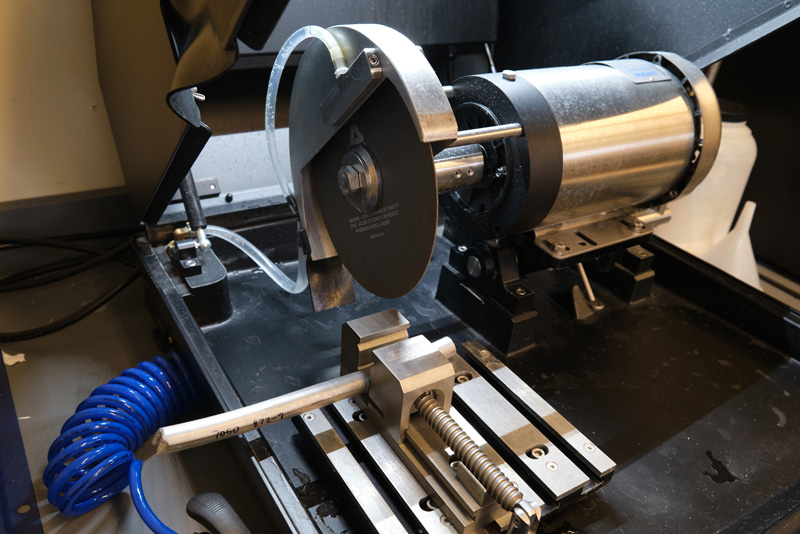

Over the past fifty-five years, Beneke has continued to expand manufacturing space and productivity. With over 200,000 square feet of production space we have the equipment and inventory to complete your job. Beneke continues to spend money to upgrade our equipment and our people to be the best specialty aluminum wire company there is.

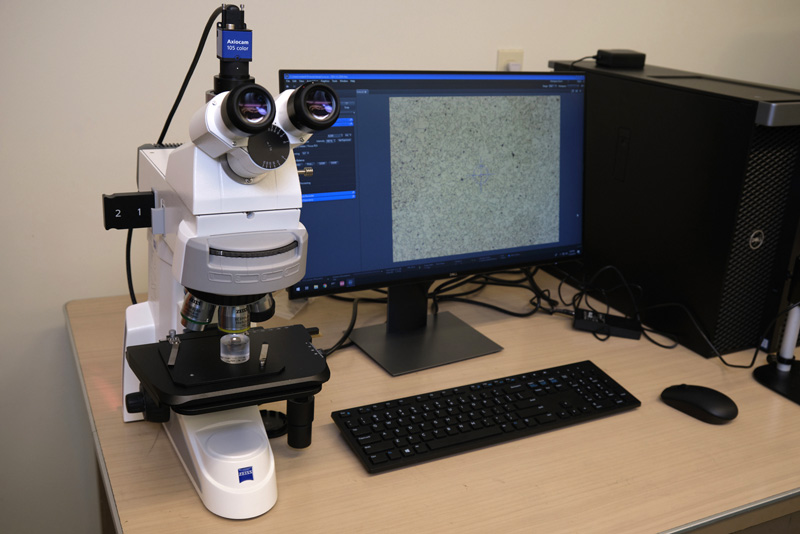

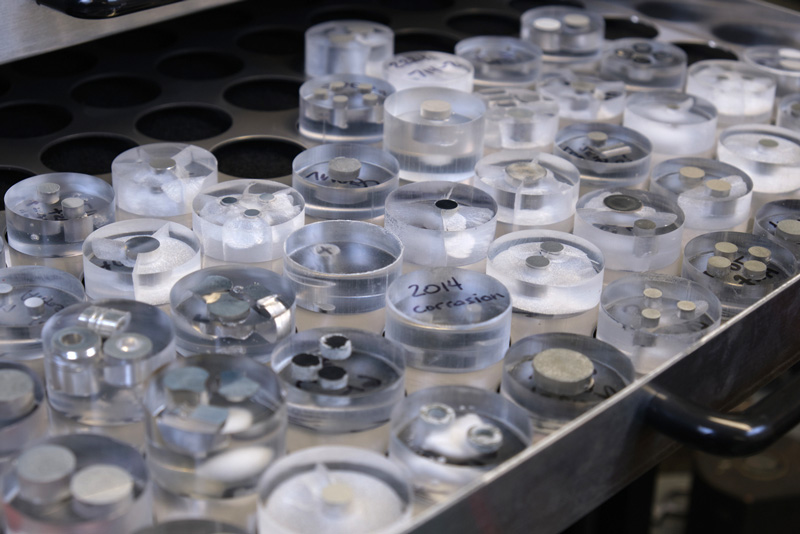

We constantly invest in our quality lab to ensure we are delivering the highest quality product for our customers.